- Overview

- Product Description

- Product Specifications

- Product Actual Shooting

- Product Details

- <span style="font-size:14px;"><span style="font-size:14px;"><span style="font-size:14px;"><span style="font-size:14px;">Working Principle</span></span></span></span>

- Application Range

- <span style="font-size:14px;"><span style="font-size:14px;"><span style="font-size:14px;"><span style="font-size:14px;">About Us</span></span></span></span>

Basic Info.

Model NO.

XC-D80H

Process Air Flow

80 M3/Hr

Process Blower

0.75 Kw

Power

400V/50Hz

N.W

34kg

Regen Heater

0.25 Kw

Regen Blower

3.5 Kw

Transport Package

Wooden Case

Specification

1670x500x780 mm

Trademark

XIECHENG

Origin

China

Product Description

Ce Standard Closed Loop Conveying System Desiccant Wheel Dryer

If you want more sizes, please contact us for details

Honeycomb Dehumidifier

Honeycomb Dehumidifier

The honeycomb dehumidifying series are mainly used to dry hygroscopic engineering plastics, , such as PA, PC, PBT, PET, etc.

The honeycomb rotor can provide stable low dew point dry air and it will not pollute the raw materials due to the aging of molecular sieve like in a double-barrel molecular sieve dehumidifier. This series provide a variety of air volume models for selection, and the maximum dry air volume can reach 4000m3/hr.

| Model | XC-D30H | XC-D50H | XC-D80H | XC-D120H | XC-D150H | XC-D200H | XC-D300H | XC-D400H | XC-D500H | XC-D700H | XC-D1000H | XC-D1500H | XC-D2000H | XC-D3000H |

| Process Air Flow(m³/hr) | 30 | 50 | 80 | 120 | 150 | 200 | 300 | 400 | 500 | 700 | 1000 | 1500 | 2000 | 3000 |

| Process Blower (kw) | 0.25 | 0.37 | 0.75 | 0.75 | 1.5 | 1.5 | 2.2 | 3.75 | 5.5 | 5.5 | 7.5 | 5.5x2 | 7.5x2 | 11x2 |

| Regen Blower (kw) | 0.25 | 0.25 | 0.25 | 0.25 | 0.37 | 0.37 | 0.75 | 0.75 | 1.5 | 1.5 | 3 | 2.2x2 | 3x2 | 4x2 |

| Regen Heater (kw) | 3 | 3 | 3.5 | 3.5 | 4 | 5.4 | 7.2 | 7.2 | 10 | 10 | 15 | 20 | 30 | 48 |

| Pipe Dia. (mm) | 2" | 2" | 2.5" | 2.5" | 3" | 3" | 3" | 4" | 4" | 4" | 5" | 6" | 6" | 8" |

| Voltage | 3Φ, 400V,50Hz | |||||||||||||

| H(mm) | 1670 | 1670 | 1670 | 1730 | 1730 | 1970 | 1970 | 1970 | 1950 | 1950 | 2210 | 2210 | 2270 | 2270 |

| W (mm) | 560 | 560 | 560 | 650 | 650 | 700 | 700 | 700 | 940 | 940 | 2260 | 2260 | 2250 | 2250 |

| D(mm) | 710 | 710 | 710 | 900 | 900 | 1200 | 1200 | 1200 | 1630 | 1630 | 1930 | 1930 | 1950 | 1950 |

| Weight (kg) | 120 | 120 | 120 | 140 | 215 | 225 | 240 | 280 | 290 | 300 | 400 | 510 | 630 | 760 |

| Cooling Water Pipe Diameter | 3/4' | 3/4' | 3/4' | 3/4' | 3/4' | 3/4' | 3/4' | 3/4' | 3/4' | 3/4' | 2' | 2' | 2' | 2' |

If you want more sizes, please contact us for details

CONTACT SUPPLIER

01 LCD Controller

Industry leading LCD microcomputer controller with temperature control accuracy of ± 0.1 ºC

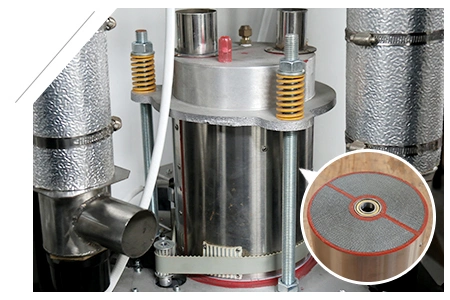

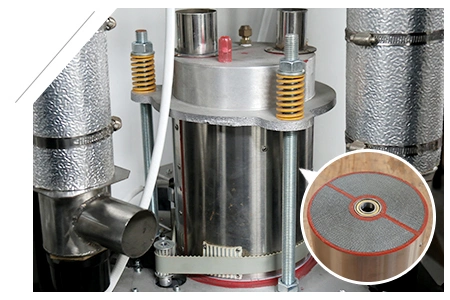

02 Honeycomb Rotor

The honeycomb rotor can provide stable low dew point dry air and it will not pollute the raw materials due to the aging of molecular sieve like in a double-barrel molecular sieve dehumidifier.

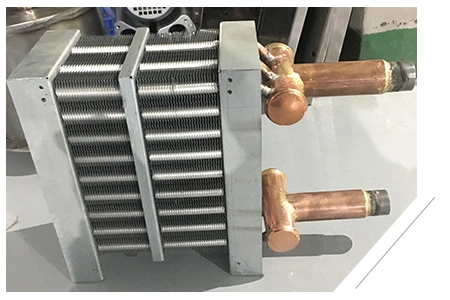

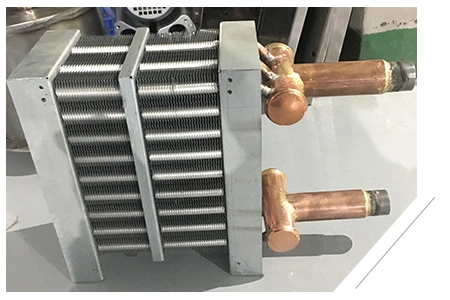

03 Double Cooler Structure

Adopted double cooler structure to ensure lower return air temperature and low dew point for the large models.

04 Air Filter

With internal return air filter to avoid dust from materials damaging the honeycomb.

Company ProfileIn 2009, founded by Mr. Fuzhibo with its head quarter in Jiangmen city which known as a famous hometown of many overseas Chinese, Jiangmen Xiecheng Machinery Co., Ltd. has been devoted herself to be an integrated enterprise of R&D, manufacturing and marketing businesses for High-end Industrial Refrigeration Equipment, Rubber and Plastic Moulding Auxiliary Automation Equipment, and also Intelligent Integrated System Solutions. Authenticated by IS09001, XIECHENG also successfully established the "6+1+C" full dimensional product service system with her own supply chain advantages of combining the six series of products, as Industrial Refrigeration, Mould Temp. Controlling, Material Conveying, Crushing & Recycling, Dehumidifying & Drying, and also Mixing, into central intelligent system solutions as Material Feeding, Air Supply, Water Supply and Power Supply, to fast fitting customers' specific demands.

Exhibition